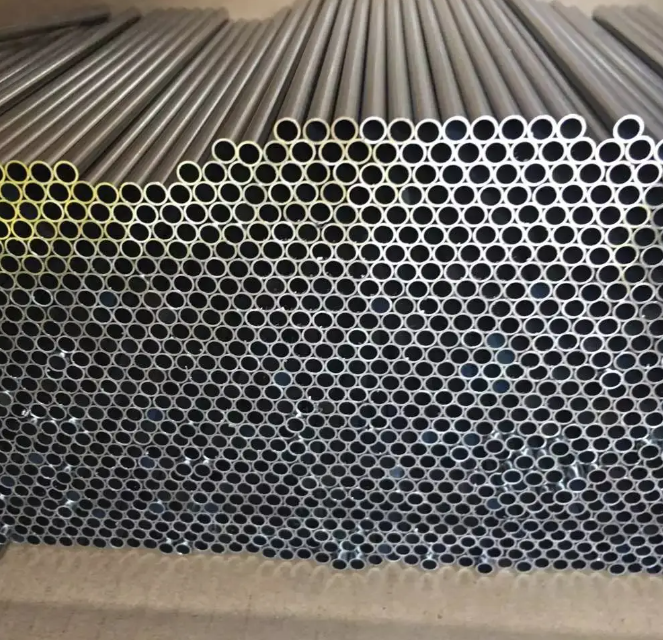

304 316L 1インチ2インチステンレスチューブ

最新の価格を取得する| お支払い方法の種類: | L/C,T/T,D/P,D/A |

| インコタームズ: | FOB,CFR,CIF,EXW |

| 輸送方法: | Ocean,Land,Express |

| お支払い方法の種類: | L/C,T/T,D/P,D/A |

| インコタームズ: | FOB,CFR,CIF,EXW |

| 輸送方法: | Ocean,Land,Express |

モデル: 201 304 304L 316 316L 301 321 410 420 441 439 409L

ブランド: Xinsuju

標準: JIS, AiSi, ASTM, GB, DIN, EN

原産地: 中国

種: 溶接

素材: 200シリーズ, 300シリーズ, 400シリーズ, 600シリーズ

認証: RoHS, ISO, IBR, BV, Sgs

溶接形状: スパイラル溶接, ERW, Efw

許容差: ±1%

処理サービス: 曲げ, 溶接, デコイル, パンチング, 切断, 成形

製品名: Stainless Steel Welded Round Pipe

Moq: 1 ton

Keyword: Stainless steel pipe

Technique: Hot Rolled Or Cold Rolled

Length: 1-12m or customized

納期: 15-30 days

Production Process: welding/ polishing

Size: customized

Surface Finish: 2B

Invoicing: by actual weight

| 販売単位 | : | Kilogram |

| パッケージ型式 | : | 標準輸出梱包 |

| 写真の例 | : |

|

The file is encrypted. Please fill in the following information to continue accessing it

| Product Name | stainless steel pipe |

| Material | 200 series: 201, 202 |

| 300 series: 304, 304L, 304H, 310S, 316, 316L, 317L, 321,310S,309S,2205,2507,2520 | |

| 400 series: 410, 410S,420, 430, 431, 440A,904L | |

| Standard | AISI, ASTM, DIN, GB, JIS, SUS |

| Thickness | 0.5mm-30mm as your request |

| Size | 8mm-530mm as your request |

| Length | 1 meters to 6 meters or as customer 's requirement |

| Treatment/Technique | Hot rolled, cold drawn, Annealed, Grinding |

| Surface | Satin,400#, 600~1000# mirrorx, HL brushed,Brushed Mirror(two kinds of finishing for one pipe) |

| Applications | Decorative /industrial/building material |

| Trade Terms | EXW, FOB, CFR, CIF |

| Delivery time | Shipped in 7-15 days after payment |

| Package | Standard sea-worthy package or as required |

| SEAWORTHY PACKING | 20ft GP: 5.8m(length) x 2.13m(width) x 2.18m(high) about 24-26CBM |

| 40ft GP: 11.8m(length) x 2.13m(width) x 2.18m(high) about 54CBM 40ft HG: 11.8m(length) x 2.13m(width) x 2.72m(high) about 68CBM |

| Stainless Steel Grades | ||||

| EN-DIN standard steel grade | EN-standard steel grade | ASTM/AISIstandard steel grade | UNS | GB-standard steel grade |

| 1.431 | X10CrNi18-8 | 301 | ||

| 1.4318 | X2CrNiN18-7 | 301LN | ||

| 1.4307 | X2CrNi18-9 | 304L |

S30403 |

|

| 1.4306 | X2CrNi19-11 | 304L | S30403 | 00Cr18Ni9 |

| 1.4311 | X2CrNiN18-10 | 304LN | S30453 | |

| 1.4301 | X5CrNi18-10 | 304 | S30400 | 06Cr19Ni10(GB/T3280-2007) |

| 1.4948 | X6CrNi18-11 | 304H | S30409 | |

| 1.4303 | X5CrNi18 12 | 305 | ||

| 1.4541 | X6CrNiTi18-10 | 321 | S32100 | 0Cr18Ni11Ti |

| 1.4878 | X12CrNiTi18-9 | 321H | S32109 | |

| 1.4404 | X2CrNiMo17-12-2 | 316L | S31603 | 00Cr17Ni14Mo2 |

| 1.4432 | X2CrNiMo17-12-3 | 316L | S31603 | 00Cr17Ni14Mo2 |

| 1.4435 | X2CrNiMo18-14-3 | 316L | S31603 | 00Cr17Ni14Mo2 |

| 1.4401 | X5CrNiMo17-12-2 | 316 | S31600 | 0Cr17Ni12Mo2 |

| 1.4436 | X3CrNiMo17-13-3 | 316 | S31600 | 0Cr17Ni12Mo2 |

| 1.4406 | X2CrNiMoN17-12-2 | 316LN | S31635 | |

| 1.4571 | X6CrNiMoTi17-12-2 | 316Ti | S31635 | |

| 1.4429 | X2CrNiMoN17-13-3 | 316LN | S31653 | |

| 1.4438 | X2CrNiMo18-15-4 | 317L | S31703 | |

| X10CrNiTi189 | 347 | 0Cr18Ni11Nb | ||

| 1.4512 | X6CrTi12 | 409 | 0Cr11Ti | |

| S41000 | 0Cr13 | |||

| 410 | 1Cr13 | |||

| 420J1 | 2Cr13 | |||

| 1.4016 | X6Cr17 | 430 | 1Cr17 | |

| 1.4118 | X40CrMo15 | 440A | S44002 | 8Cr13 |

| 1.4112 | 440B | S44004 | 9Cr13 | |

| 1.4125 | 440C | S44003 | 11Cr18 | |

| 440F | S44020 | |||

| 1.4539 | X1NiCrMoCu25-20-5 | 904L | N08904 | 00Cr20Ni25Mo4.5Cu |

| 1.4547 | X1CrNiMoCuN20-18-7 | S31254 | ||

|

Austenitic Stainless Steel

|

201, 301, 304, 305, 310, 314, 316, 321, 347, 370, etc

|

|||

|

Martensitic Stainless Steel

|

410, 414, 416, 416, 420, 431, 440A, 440B, 440C, etc

|

|||

|

Duplex Stainless Steel

|

S31803, S32101, S32205, S32304, S32750, etc

|

|||

|

Ferritic Stainless Steel

|

429, 430, 433, 434, 435, 436, 439, etc

|

|||

|

chemical component ( %)

|

|||||||

|

Grade ASTM

|

C

|

Si

|

Mn

|

S

|

P

|

Cr

|

Ni

|

|

201

|

≤0.15

|

≤0.75

|

5.50-7.50

|

≤0.030

|

≤0.060

|

16.00-18.00

|

3.50-5.50

|

|

304

|

≤0.07

|

≤1.00

|

≤2.00

|

≤0.030

|

≤0.035

|

17.00-19.00

|

8.00-11.00

|

|

304L

|

≤0.03

|

≤1.00

|

≤2.00

|

≤0.030

|

≤0.035

|

18.00-20.00

|

8.00-12.00

|

|

309S

|

≤0.08

|

≤1.00

|

≤2.00

|

≤0.030

|

≤0.035

|

22.00-24.00

|

12.00-15.00

|

|

310S

|

≤0.08

|

≤1.00

|

≤2.00

|

≤0.030

|

≤0.035

|

24.00-26.00

|

19.00-22.00

|

|

316

|

≤0.08

|

≤1.00

|

≤2.00

|

≤0.030

|

≤0.045

|

16.00-18.00

|

10.00-14.00

|

|

316L

|

≤0.03

|

≤1.00

|

≤2.00

|

≤0.030

|

≤0.035

|

16.00-18.00

|

12.00-15.00

|

ステンレス鋼パイプの生産プロセス: 丸い鋼製の準備 - 加熱 - ホットローリングピアス - ヘッドカッティング - 漬物 - 粉砕 - 潤滑 - コールドローリング処理 - 脱脂 - 溶液熱処理 - 矯正 - パイプ切断 - 酸化 - 完成品検査。

産業用トランスミッションパイプラインや、化学産業などの機械的構造部品で広く使用されています。

治療、食品、光産業、機械、機器。

よくある質問

Q:あなたの利点は何ですか?A:もちろん、当社の製品はすべて、パッケージング前に品質について厳密にテストされており、資格のない製品が破壊されます。

その他の製品: 304ステンレス鋼ラウンドロッド、ASTMステンレス鋼ラウンドバー、炭素鋼シームレススチールパイプ、炭素鋼パイプ、炭素鋼シームレス鋼管、銅、DX51亜鉛メッキロール、亜鉛メッキコイル、亜鉛メッキパイプ

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.